Thermofloor

Thermofloor from Weiss raised floor systems

Thermo floors can be used in almost all areas, from new constructions up to complete renovations of old objects. On thermofloors all floor coverings, suitable for underfloorheating, can be used:

At the present time, out of economic and ecological view, rooms are heated and cooled via activated surfaces and the room climate is regulated through pleasant radiant heat. The big advantage of thermo floor shows in the costs, because the larger the heated surface, the less energy has to be used.

Description

Description

Consequently, the costs of heating and cooling are reduced and, in addition, the environment is less burdened and with the help of calcium sulfate plates an optimal heat transport is guaranteed.

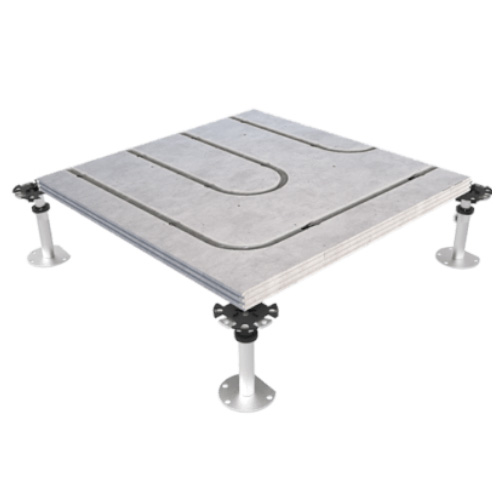

The pipes for the underfloor heating are set in a special milling in the panel and then closed with putty.

The used pipes are made of highly cross-linked polyethylene, which clearly surpasses the oxygen-tightness of standard requirements.

In the substructure pedestals are used, which can be adjusted exactly in height.

Installation

1. Build up

The hollow floor with prefabricated millings for the heating medium is built up first, according to the installation plan.

2. Clipping

Subsequently the plastic tube is clipped into the holding grooves.

3. Cutouts

Cutouts can be prefabricated (for example for electric floor tanks).

4. Testing

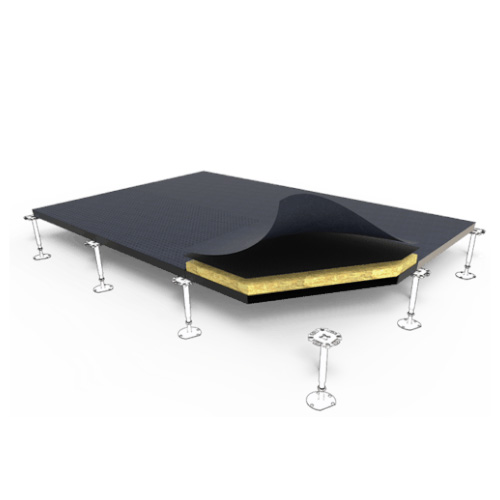

After the pipes have been tested for leaks, the pipes are embedded with a special filling compound.

5. Solidifaction

After consolidation, the overhang is pushed off flush with the surface to create a high quality flat surface.

6. Covering

After functional heating the cover can be laid.

Charts

| Heating operation | pipe grid 100 mm | pipe grid 150 mm |

| Heat flux density qG according to | ||

| DIN EN 1264-2 (without covering, R = 0,00 m² K / W) | 77 W/m² | 60 W/m² |

| at standard heating medium excess temperature ΔθH | 11,69 K | 12 K |

| Heat flow density qG according to | ||

| DIN EN 1264-2 | 89 W/m² | 78 W/m² |

| at standard heating medium excess temperature ΔθH | 25,89 K | 29 K |

| Cooling mode | pipe grid 100 mm | pipe grid 150 mm |

| Specific cooling capacity q according to | ||

| DIN EN 1264-5 | 38,2 W/m² | 28,7 W/m² |

| Coolant temperature ΔθH | 8 K | 8 K |

Thermal properties

Always incorporate Floor Plus Thermo expansion, movement and connection joints in the floor covering.

Thermofloor is chair castor resistant without additional measures.

Priming with Knauf Estrichgrund F431 or priming of the adhesive system used.

Carpets can be laid without full-surface levelling, depending on the carpet material.

It may then be necessary to fill the joint areas, e.g. with Knauf Uniflott.

When laying elastic thin coverings (e.g. PVC, linoleum, rubber), a full-surface levelling of at least 2 mm thickness is required (e.g. with Knauf Nivellierspachtel 415), followed by priming.

Primers, levelling compounds and adhesives must be matched to each other and to the substrate and floor covering.

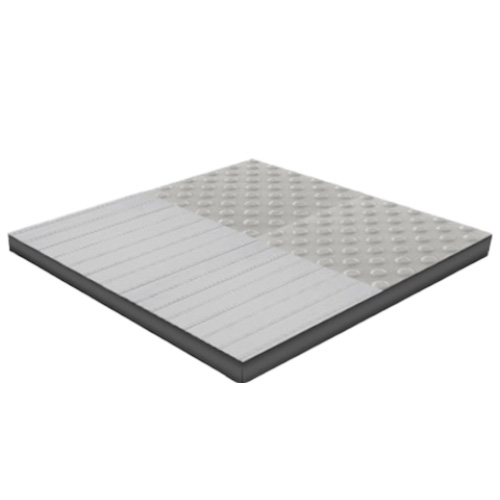

Lay ceramic tiles and natural stone coverings with flexible adhesive systems.

The processing instructions of the adhesive system manufacturer for the covering formats used, in particular the specified minimum adhesive bed thicknesses, must be observed.

must be observed.

The use of nonwovens and fabrics belonging to the adhesive system is possible.

If the permissible deflections due to expected loads on the Floor Plus Thermo are greater than the deformations that can be absorbed by the floor covering, the necessary additional measures must be planned.

To further limit these deflections, e.g. install larger element thicknesses and/or additional supports, e.g. arranged in the centres of the grid panels.

Floating installation of parquet or parquet thickness ≤ 1/2 of the thickness of the base layer; the processing instructions of the parquet and adhesive system manufacturer for the selected type of parquet must be observed.

Liquid coatings such as epoxy resin coatings must be elasticised.

Check the adhesive tensile strength of the covering/adhesive system or the coating to the Floor Plus Thermo (if necessary, prepare a sample).

The physical conditions of the building must be taken into account when selecting the coating system.

Primers, levelling compounds, adhesives and system-related fleeces and fabrics must be matched to each other.

The expected movements of the floor system must be absorbed by appropriate expansion joints. Check (if necessary, make a sample).

The physical conditions of the building must be taken into account when selecting the coating system.

Primers, levelling compounds, adhesives and system-related fleeces and fabrics must be matched to each other.

The expected movements of the floor system must be absorbed by appropriate expansion joints.

Charts

| Heating operation | pipe grid 100 mm | pipe grid 150 mm |

| Heat flux density qG according to | ||

| DIN EN 1264-2 (without covering, R = 0,00 m² K / W) | 77 W/m² | 60 W/m² |

| at standard heating medium excess temperature ΔθH | 11,69 K | 12 K |

| Heat flow density qG according to | ||

| DIN EN 1264-2 | 89 W/m² | 78 W/m² |

| at standard heating medium excess temperature ΔθH | 25,89 K | 29 K |

| Cooling mode | pipe grid 100 mm | pipe grid 150 mm |

| Specific cooling capacity q according to | ||

| DIN EN 1264-5 | 38,2 W/m² | 28,7 W/m² |

| Coolant temperature ΔθH | 8 K | 8 K |

Panel

| Base layer | gypsum fiber board 40 mm/td> |

| Support plate | 600 x 600 mm with trapezoidal tooth profile and heating tube groove |

| Diffusion barrier | underside aluminum coating / for higher loads underside steel sheet |

| System weight | ca. 64 kg/m² |

| Laying distance | 150 mm, 100 mm, edge zones possible |

| Heating pipe | polyethylene Alternative: Roth multi-layer composite tube Alu-Laserflex 16 x 2 mm oxygen-tight according to DIN 4726 Multilayer composite pipe possible |

| Fillers | Special filling compound, castor-proof, temperature-resistant |

Subconstruction

| Pedestal grid | 600 x 600 mm |

| Reinforcement border area | None, grid bar or other reinforcement measure |

| Pedestal material | steel, galvanized |

Load Values

| Point load: | 3.000 / 4.000 / 5.000 (15,000 N in connection with 30mm stone pavement) |

| Element class accord. to DIN EN 13213 | load class 3 / 4 / 5 / 6 |

| Breaking load | ≥ 6000/8000/10 000/30 000 N |

Cover

| Material | textile and elastic floor coverings, parquet, natural stone, artificial stone, ceramics |

| Functional heating: | from 36 hours after casting for 48 hours |

| The maturity of the floor structure | immediately after the functional heating and cooling |