Acoustic panel

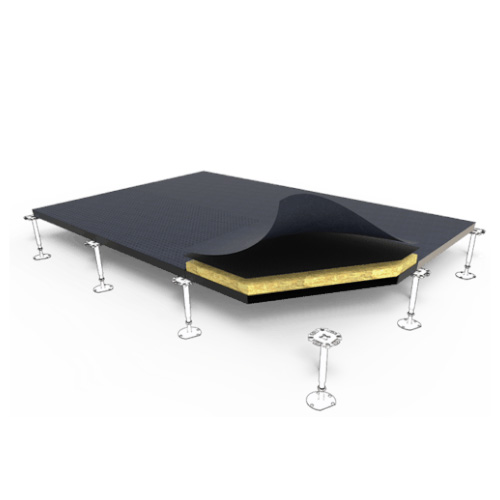

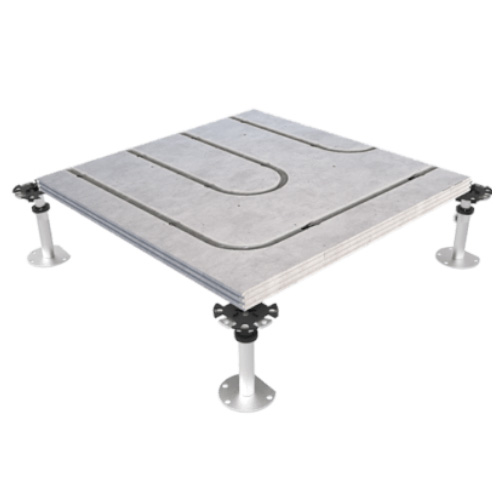

Acoustic panel from Weiss Raised floor systems

Modern architecture uses a high proportion of sound-reflecting materials such as e.g. Exposed concrete and glass, which influence the reverberation time unfavorably. As a result of this – beside room facilities and people – practically only the floor is available as absorption area.

Type and extent of sound absorption in the acoustics raised floor panel are determined by three elements:

- carpet

- Hole grid of the bottom plate

- absorber

Each of these three components significantly influences the measured and sensorially perceived result of the achieved modern room acoustics.

Description

Description

By varying the three elements, the acoustic raised floor can be adapted to the respective requirements.

Advantages:

- Sound reflecting is absorbed through the carpet into the panel element

- Significantly improved absorption values compared with any other hollow floor solution

- No effects on the installations in the hollow space

- No restrictions on the ventilation through the hollow space

- Combinations with conventional panel elements assured

- The mechanical and static properties are maintained

- Different versions provide «made-to measure acoustics»

- We use the know-how acquired by the market leader for modern acoustic panels

Horstmann & Berger (Altensteig/D) were responsible for calculating the acoustics. Each of these three components (carpet, hole pattern, absorber) exerts a significant influence on the perceived and measured results of the implemented modern room acoustics and sound reflecting.

The three elements can be varied to adapt an acoustic raised floor to meet the specific requirements. Part of the campus project for Novartis Pharma AG in Basel, the modern Sanaa Building is a classic example of the way in which acoustic raised floor panels can be used.

This newly constructed 6-storey building complex comprises two longitudinal wings, each measuring 5.6 x 84 meters, and most of the rooms are used as modern offices. The longitudinal facades are completely made of glass and fair-faced concrete has been used for the walls and ceilings.

System description

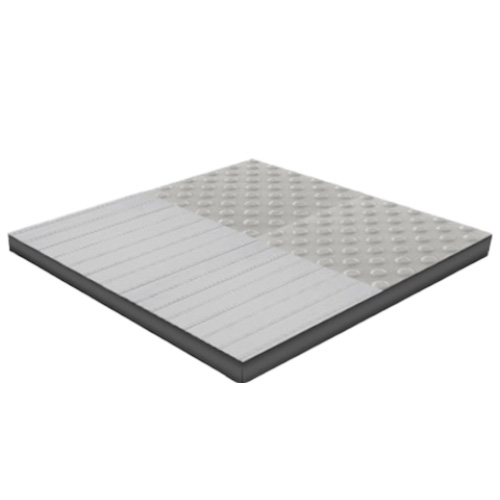

Floor covering

Perforated loose-lay carpet tiles.

Panels

Acoustic panels made of perforated steel with integrated absorbers. Galvanized 1.00 mm steel plate on the underside. Protective film on top, which must be removed before fitting the floor covering! Fiber-reinforced peripheral zones and under-wall regions with panels made of fiber-reinforced calcium sulfate.

M16 Pedestals

Made of galvanized blue-passivated steel, the pedestals have a stepless height adjustment facility and are characterized by the precision guidance for the adjusting pin.

Bolt locking

Bolt adhesive or a mechanical locking device

Adhesive bonding

Bedding the base of the pedestal in pedestal glue

Installation height

Stringers are used for installation heights of 500 mm and more (optional)

Wall connection

Permanently pretensioned wall connection with sealing tape for acoustic decoupling and to absorb movement.

Unfinished floor

It is advisable to apply a floor coating to seal unfinished floors where air ducting installation panels are to be fitted.

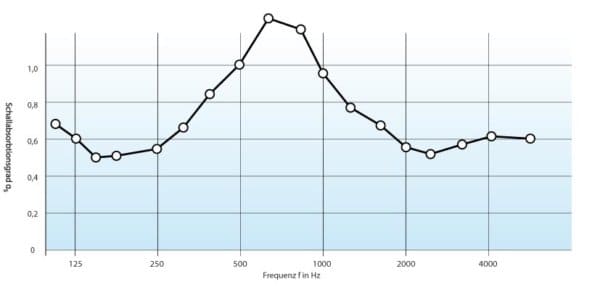

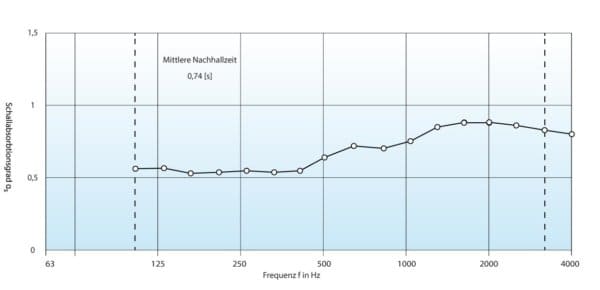

Reverberation time

Coverian Variants

Velours Chromojet-patterned, tufted, Measurement 56

| Manufacturer, type: | Anchor, Office 750 Element |

| Format | >600 x 600 mm |

| Total thickness: | >6.3 mm |

| Pole weight: | ca. 770 g/m2 |

| Back | EVA |

| Numbers of colors: | Design and colors as desired |

| Perforation: | yes |

Evaluation according to DIN EN ISO 11654/97 | Rated sound absorption coefficient w = 0.75 (M) | Maximum sound absorption 1.0.

Sling mottled, tufted, Measurement 57

| Manufacturer, type: | Anchoer, Aera_E Element |

| Format | 600 x 600 mm |

| Total thickness: | 6.0 mm |

| Pole weight: | ca. 700 g/m2 |

| Back | EVA |

| Numbers of colors | 25 |

| Perforation | yes |

Evaluation according to DIN EN ISO 11654/97 | Rated sound absorption coeffi cient w = 0.65 (M) | Sound absorber class : C | Maximum sound absorption 1.0.

Velours patterned, tufted, Measurement 58

| Manufacturer, type: | Anchor, Alba_E Element |

| Format | 600 x 600 mm |

| Total thickness: | 6.5 mm |

| Pole weight: | ca. 710 g/m2 |

| Back | EVA |

| Numbers of colors:/strong> | 24 |

| Perforation | yes |

Evaluation according to DIN EN ISO 11654/97 | Rated sound absorption coeffi cient w = 0.70 (M) | Sound absorber class : C | Maximum sound absorption 1.0.

Velours mottled, tufted, Measurement 59

| Manufacturer, type: | Anker, Delta_E Element |

| Format | 600 x 600 mm |

| Total thickness: | 6.5 mm |

| Pole weight: | ca. 710 g/m2 |

| Back | EVA |

| Numbers of colors: | 25 |

| Perforation: | ja |

Evaluation according to DIN EN ISO 11654/97 | Rated sound absorption coefficient w = 0.70 (M) | Maximum sound absorption 1.0.

Velours mottled, tufted, Measurement 60

| Manufacturer, type: | Anchor, Delta-Plus_E Element |

| Format | 600 x 600 mm |

| Total thickness: | 7.4 mm |

| Pole weight: | ca. 900 g/m2 |

| Back | EVA |

| Numbers of colors: | 25 |

| Perforation: | yes |

Evaluation according to DIN EN ISO 11654/97 | Rated sound absorption coeffi cient w = 0.80 (M) | Sound absorber class : C | Maximum sound absorption 1.0.

Velours uni, tufted, Messung 61

| Manufacturer, type: | Anker, Delta_E Element |

| Format | 600 x 600 mm |

| Total thickness: | 7,6 mm |

| Pole weight: | ca. 710 g/m2 |

| Back | EVA |

| Numbers of colors: | 25 |

| Perforation | yes |

Evaluation according to DIN EN ISO 11654/97 | Rated sound absorption coefficient w = 0.70 (M) | Maximum sound absorption 1.0.

Slinge nottled, tufted, Measurement 62

| Manufacturer, type: | Anker, Aera_E Element |

| Format | 600 x 600 mm |

| Total thickness: | 6.0 mm |

| Pole weight: | ca. 700 g/m2 |

| Back: | EVA |

| Numbers of colors: | 25 |

| Perforierung | yes |

Evaluation according to DIN EN ISO 11654/97 | Rated sound absorption coefficient w = 0.65 (M) | Maximum sound absorption 1.0.

Velours Heat-Set, tufted, Measurement 63

| Manufacturer, type:/strong> | Anker, Aera_E Element |

| Format | 600 x 600 mm |

| Total thickness: | 6.8 mm |

| Pole weight: | ca. 1000 g/m2 |

| Back: | EVA |

| Numbers of colors:/strong> | 24 |

| Perforation: | yes |

Evaluation according to DIN EN ISO 11654/97 | Rated sound absorption coefficient w = 0.65 (M) | Maximum sound absorption 1.0.