Hollowfloor

Hollowfloor from Weiss raised floor systems

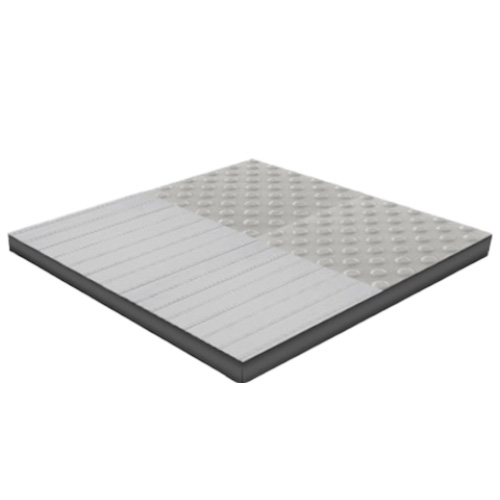

Hollow floors offer an economic alternative floor system to a raised floor.

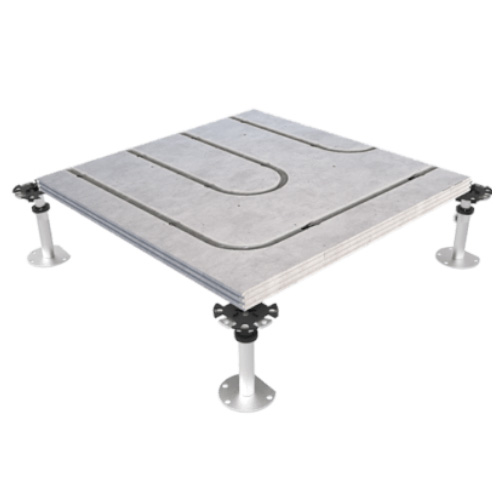

Gypsum panels are used for dry-type floors. These panels are tongued and grooved together and bonded. The panels are gaplessly connected, which means that, once installed, it will no longer be possible to remove panels individually.

Inspection openings offer a means of accessing the installation in the hollow space.

Description

Description

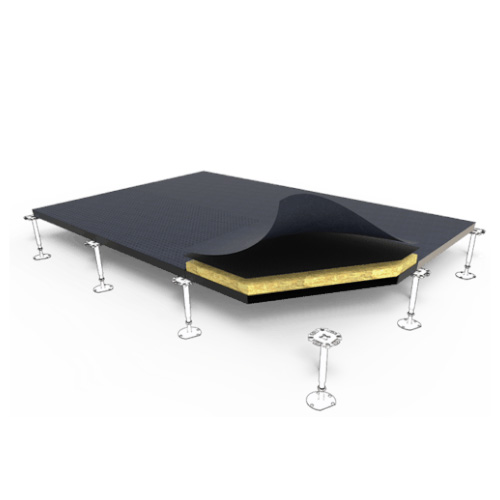

The great advantage of this construction is that it prevents the ingress of unwanted dampness into the building and avoids the delays while waiting for screed surfaces to dry.

They weigh much less than conventional hollow floor systems and they offer more free space for installations thanks to the reduction in floor height. A dry-type Hollow floor is the ideal solution for particularly expeditious construction projects.

Preference is given to the use of hollow floors in offices and administration buildings. These floors are also fitted in rooms used for training, research and production purposes as these panels have a high load bearing capacity.

Tongue and groove

| Element acc. to EN 15283-2 | Element effective measurement mm | Element thickness mm | Weight (Density ≥ 1500 kg/m3) approx. kg/pcs. |

| FHB 25 | 1200 x 600 | 25 | 27,0 kg |

| FHB 25 | 600 x 600 | 25 | 13,5 kg |

| FHB 28 | 1200 x 600 | 28 | 30,2 kg |

| FHB 28 | 600 x 600 | 28 | 15,1 kg |

| FHB 32 | 1200 x 600 | 32 | 34,6 kg |

| FHB 32 | 600 x 600 | 32 | 17,3 kg |

| FHB 38 | 1200 x 600 | 38 | 41,2 kg |

| FHB 38 | 600 x 600 | 38 | 20,6 kg |

Tooth milling

| Element acc. to EN 15283-2 | Element effective measurement mm | Element thickness mm | Weight (Density ≥ 1500 kg/m3) approx. kg/pcs. |

| FP 410-25 | 600 x 600 | 25 | 15,2 kg |

| FP 410-28 | 600 x 600 | 28 | 16,1 kg |

| FP 410-30 | 600 x 600 | 30 | 18,3 kg |

| FP 410-32 | 600 x 600 | 32 | 19,0 kg |

| FP 410-34 | 600 x 600 | 34 | 21,6 kg |

| FP 410-36 | 600 x 600 | 36 | 23,5 kg |

| FP 410-38 | 600 x 600 | 38 | 24,2 kg |

| FP 410-40 | 600 x 600 | 40 | 24,9 kg |

Load increase

| Element acc. to EN 15283-2 | Element effective measurement mm | Element thickness mm | Weight (Density ≥ 1500 kg/m3) approx. kg/pcs. |

| LEP 13 | 1200 x 600 | 13 | 14,1 |

| LEP 18 | 1200 x 600 | 18 | 19,5 |